Quality

High quality finished products and service is our strength. We comply with global ISO, EN, DIN, ASTM, ANSI, BS quality standards as well as strict internal company standards and individual requirements of our customers. Production takes place under the supervision of experienced quality engineers supported by the latest measurement equipment and dedicated IT solutions.

The quality of rubber and silicone compounds used in production has been confirmed with international certificates such as KIWA, WRAS, W270, PZH, KTW, DVGW, NSF, FDA.

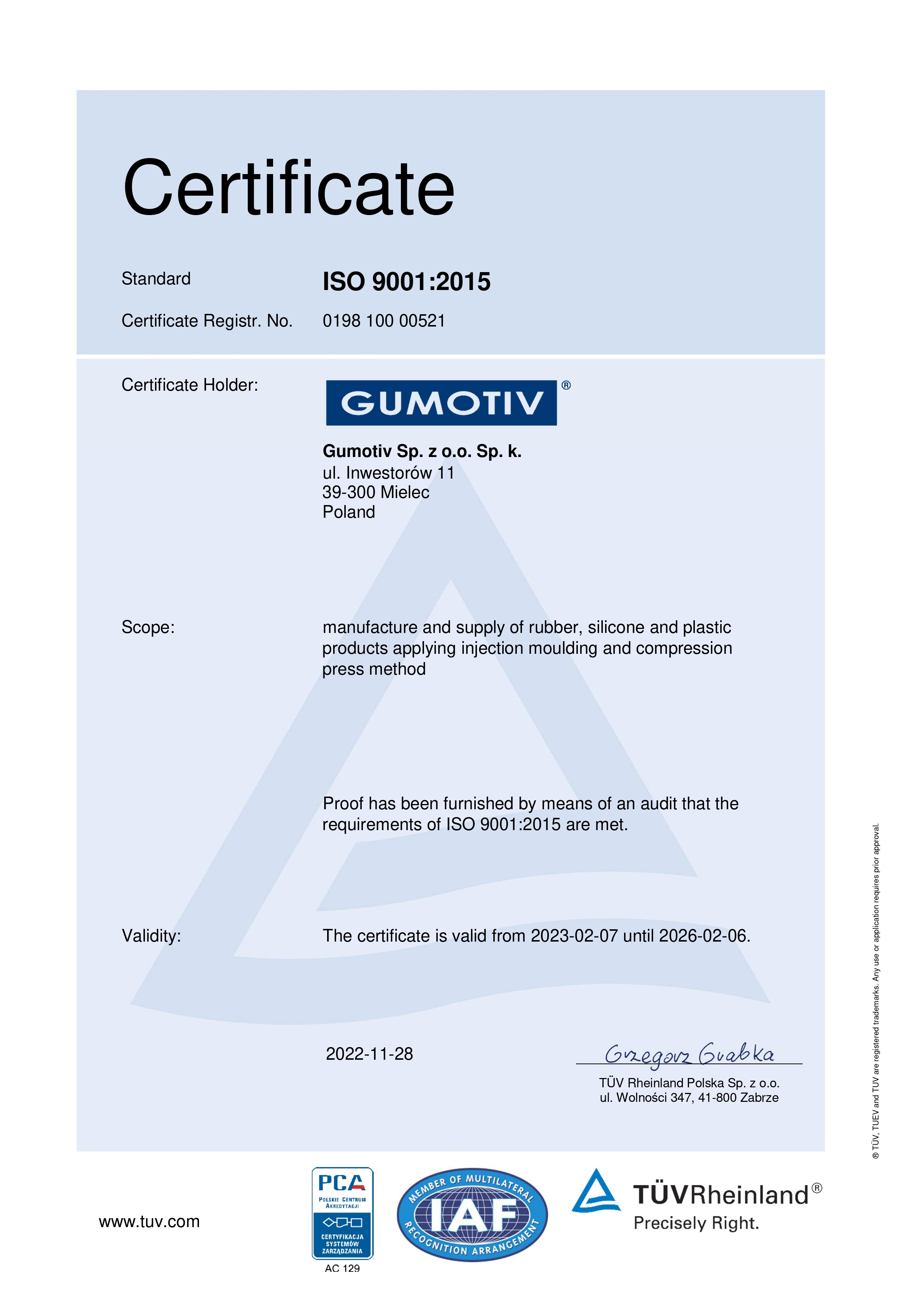

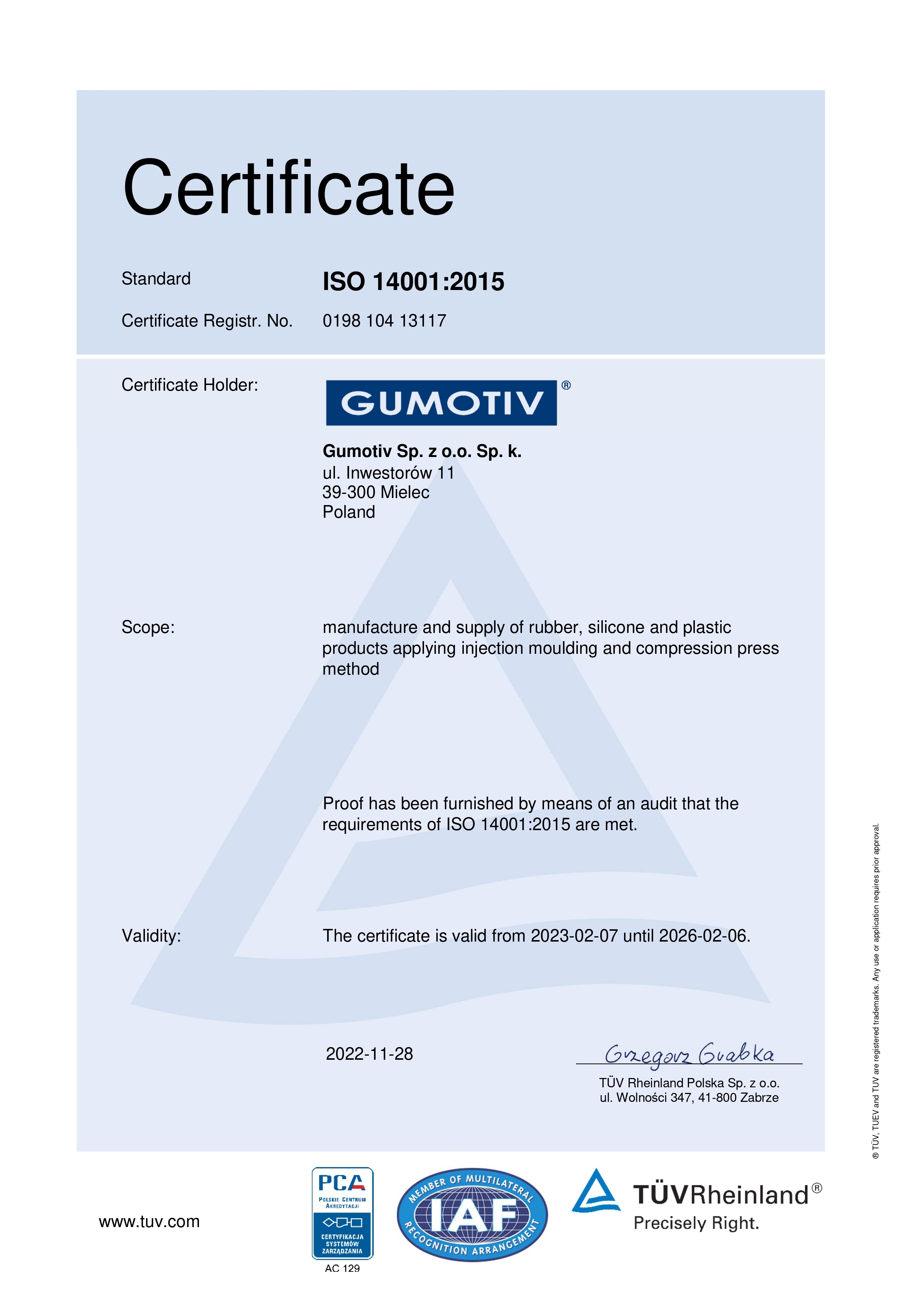

Our commitment to quality and professionalism is confirmed by the positive results of dozens of audits carried out yearly by customers and external certification bodies.

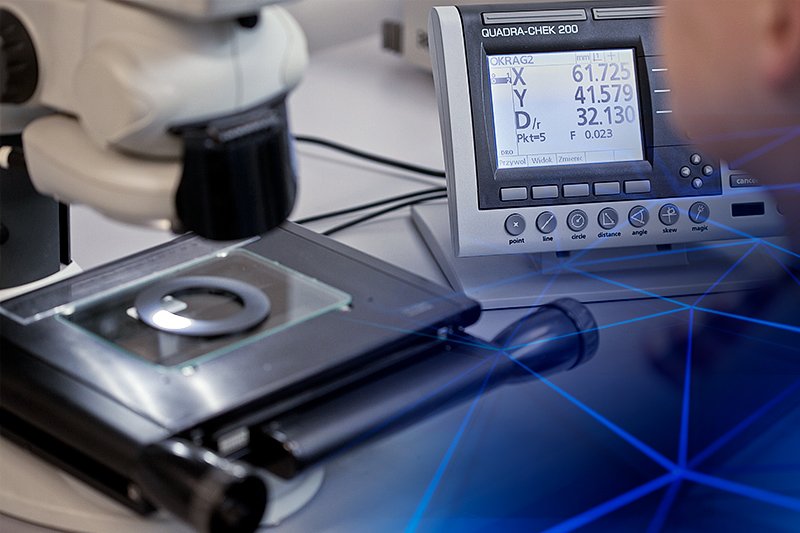

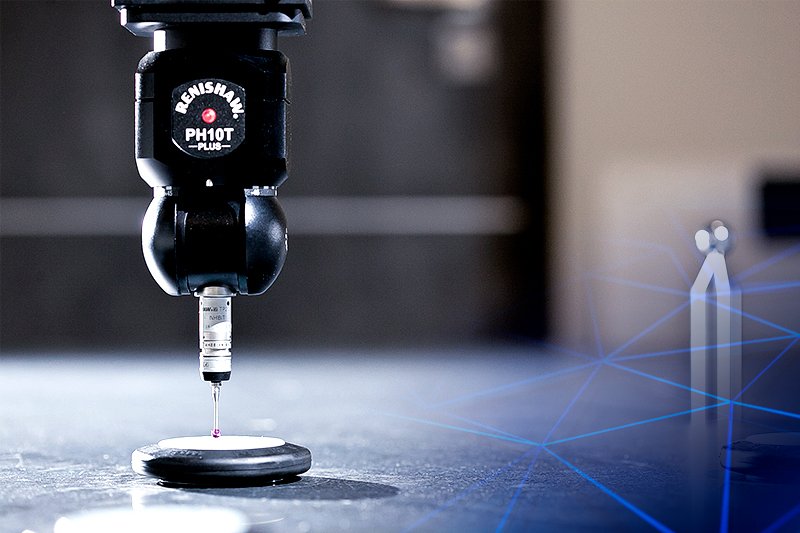

Precision More than 50 measuring devices calibrated in accredited external laboratories.

Reliable quality ISO 9001, ISO 14001, OHSAS 18001 Integrated Quality Management System certified by TÜV.

Process capability Supervision of process capability through SPC analysis and use of multiple quality-related tools. APQP, PPAP, FMEA, 8D procedures.

Monitoring of indicators Close observation of more than 15 different indicators, e.g. scrap rate, PPM, complaint rate, quality costs.

Prediction Identification of potential threats through reliable FMEA analysis at the design, implementation and process optimization stages.

Training Continuous development and improvement of staff through professional external training.

Laboratory

Our laboratory is equipped with more than 50 high quality control and measuring instruments, which are regularly calibrated by external laboratories with PCA accreditations. Hundreds of tests per week as part of ongoing production control translates into process stability and reduced rejection rate. Advanced IT systems allow for full traceability of the process, from the receipt of raw materials to the dispatch of the finished product.

Tensile and breakaway strength, hardness, compression set, heat ageing, resilience, wear and tear resistance, dielectric properties, rheology, volume change in water and oils, resistance to detergents are just a few of the many tests to which our products and rubber compounds are subjected in order to meet the most exacting requirements of our customers.